Prototyping

To bring your product to life, I offer prototyping, 3D printing, and low-volume production services. From rough proof of concept models, to functional prototypes for design validation and testing, to finely finished prototypes that match what the final product will look like, I can cover all your prototyping needs from start to finish,

Physical prototypes and proof of concept models can be an invaluable tool during the design process and also serve to validate a design, allow for testing, and attract investors. They could also be the final product themselves for one-offs and low-volume production.

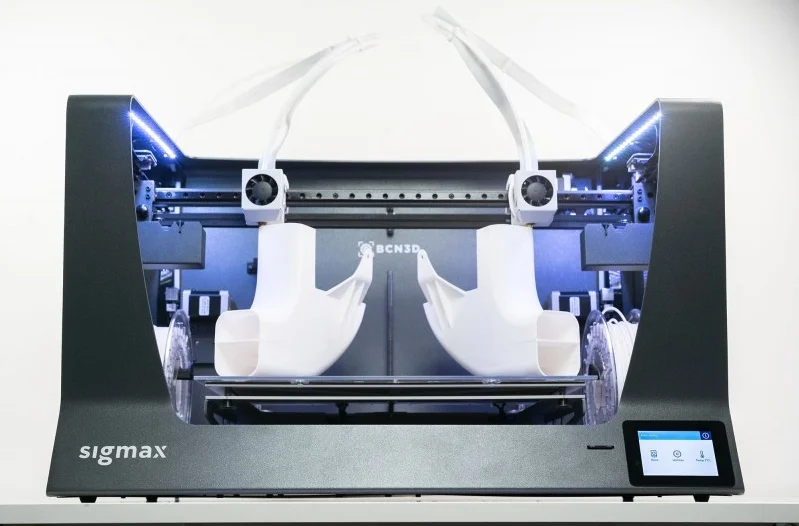

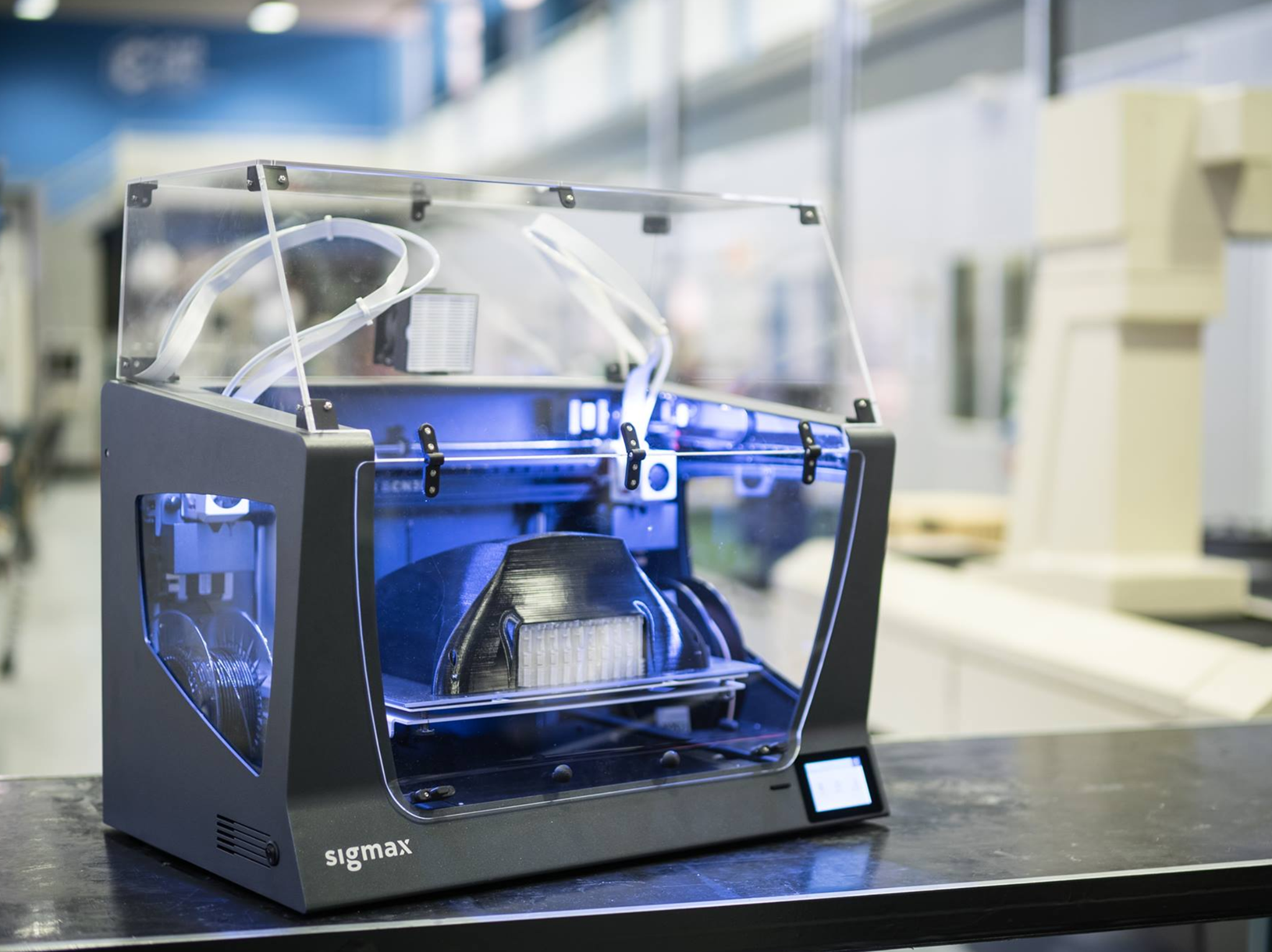

BCN3D Sigmax Large-Format Independent Dual Extruder 3D Printer

Ultimaker 2 Extended+ 3D Printer

Additional capabilities through local, domestic, and international manfacturing and equipment-sharing partners include CNC machining, laser cutting and marking, water jet cutting, injection molding, welding, metal 3D printing, and sheet metal fabrication.

In addition to the vast array of high-quality 3D printing options I offer, I also take care of other basic prototyping needs with my ever-expanding list of capabilities, including thread-tapping, hole-drilling, cutting, routing, thermoplastic bending, soldering and basic electric circuit assembly, part bonding, surface finishing (sanding, tumbling, chemical vapor treatment), painting and assembly. I stock a large supply of off-the-shelf hardware such as screws, nuts, washers, electrical components, wire, pipe, spacers, magnets, rubber bumpers, adhesives and springs for quick prototype turnaround. I can also source whatever other components you may need.

For prototyping needs I can't take care of in-house, I frequently work with numerous local, domestic and international manufacturers and equipment-sharing partners with additional capabilities. Examples include CNCing, water jet cutting, laser cutting, milling, laser marking, anodizing, welding, injection molding, metal 3D printing, dip molding, punching, bending, and extruding.

3D Printer Info

Model: Ultimaker 2 Extended+

Huge Usable Build Volume: 223 x 223 x 305 mm (8.8 x 8.8 x 12.0 in)

Best Available Resolution: 0.02mm (20 Micron) minimum layer thickness

Many material and color options: PLA, ABS, flexible and rubber-like plastics, CPE, nylon, PET, metal-filled, carbon fiber-filled, transparent, glow-in-the-dark, high-temperature plastics, in any color imaginable

Available Materials:

PLA {Polylactic Acid): The most common printer material used today. Corn-based, bio-degradable, and unlike other commonly used materials, doesn't give off hazardous fumes while printing. This is the easiest material to print with, and is my go-to for most prints, unless there are reasons to do otherwise. Available in a wide range of colors.

ABS (Acrylonitrile Butadiene Styrene): Originally the most commonly used 3D printing material, ABS has now fallen out of favor to PLA. However, ABS still has its benefits, including improved strength and flexibility over PLA as well as the ability to be chemically smoothed.

CPE: Similar properties to ABS, but without the harsh fumes.

Flexible PLA: Similar to PLA, but formulated in a way that gives it rubber-like characteristics.

Nylon: Extra tough and strong for mechanical parts.

Exotics: Examples include plastics with metal, wood, or even carbon fiber infills to give different aesthetic or functional properties.

Finishing: Due to the inherent nature of the 3D printing process, which builds up parts one layer at a time, the individual layer lines are typically visible to some degree. This is fine for most purposes, but if you would like, there are a variety of finishing options available (for an additional fee). It is possible to smooth over ABS using an acetone vapor bath. The resulting appearance is smooth and glossy, similar to an injection molded part, and has the added benefit of increasing part strength by better bonding the layers. It is also possible to mechanically tumble any material (think rock tumbler), as long as the part isn't too big or fragile, with a variety of abrasive materials to help smooth out a part. I can also fuse together extra large parts that must be printed in separate batches and paint, cut, drill, tap, and assemble parts.

Electrical

Many products these days have at least some electrical features. Electronics aren't my specialty, but I have the skills and tools to get many simpler jobs efficiently and effectively completed without the need to bring in additional personnel. For more involved work, I know when to utilize outside, professional help.

Tools include:

Fluke 87V Industrial Multimeter

Fluke 325 True RMS AC/DC Clamp Meter

Hakko FX-888D Digital Soldering Station

An inventory of commonly-used electrical components to cover most basic electrical prototyping needs, including power supplies, breadboards, resistors, capacitors, thermistors, diodes, LEDs, buzzers, wire, connectors, soldering tools and consumables, switches, buttons, Arduino microcontrollers, and heat-shrink tubing.

3D Printing

BCN3D Sigmax Independent Dual Extruder 3D Printer

Ultimaker 2+ Extended 3D printer

Custom designed humidity-controlled filament storage and feeding system

A huge inventory of 3D printing filaments (materials)

Fabricating

Taps, dies, drills, deburring tools, cutting, drill presses, grinders, welding equipment, hand tools, table saw, jointer, air compressor, rotary tools, router, metal saws, miter saws, abrasive saws, sewing machine, plastic bending, etc.

Environmental Temperature Testing Chamber

Test the real-world temperature performance of your product using a high-end temperature chamber and data acquisition tools. TestEquity 107 Benchtop Temperature Chamber with data logging. -42°C to +130°C temperature range. Inside dimensions: 12" W x 9" H x 11.25" D, Modified DUT (Device-Under-Test) DUT sensor option. Fluke 2638A Hydra Series III data acquisition system with up to 20 thermocouples. Wireless temperature and humidity data logging inside the chamber.

Precision Measuring

A highly-functional collection of precision measuring instruments including digital calipers, digital micrometers, angle measuring tools, screw pitch gauges, hole depth gauges, feeler gauges, squares, and precision rulers from industry-leading brands like Mitutoyo and Starrett. I have the capability of repeatedly measuring with an accuracy and resolution of 0.00005 inch (0.001 mm).